The camshaft position sensor is also called the cylinder identification sensor. In order to distinguish it from the crankshaft position sensor (CPS), the camshaft position sensor is generally represented by CIS. The function of the camshaft position sensor is to collect the position signal of the valve camshaft and input it to the ECU, so as to perform sequential fuel injection control, ignition timing control, and detonation control. In addition, the camshaft position signal is used to identify the moment of the first ignition when the engine is started. Because the camshaft position sensor can identify which cylinder piston is about to reach the top dead center, it is called a cylinder identification sensor.

Camshaft position sensor location

Table of Contents

The camshaft position sensor is generally installed at the position where the front end of the camshaft cover faces the front end of the intake and exhaust camshafts.

Camshaft Position Sensor Functions

Next, Easybom will elaborate on “what does a camshaft position sensor do”.

The function of the camshaft position sensor: The camshaft controls the intake and exhaust valves. It rotates at half the speed of the crankshaft, and its position determines whether the piston moving at the top dead center is at the top dead center of the compression stroke or the top dead center of the exhaust stroke. During starting, the two top dead centers cannot be distinguished from the crankshaft position signal alone. At this time, the camshaft position sensor plays a role in accurately judging the compression top dead center position.

In contrast, when the vehicle is running, the signal generated by the crankshaft speed sensor is already sufficient to determine the state of the diesel engine. That is to say, if the camshaft position sensor fails during vehicle operation, the ECU can still determine the state of the diesel engine.

The camshaft position sensor uses the Hall effect to determine the position of the camshaft: a tooth made of ferromagnetic material is provided on the camshaft, which rotates with the camshaft.

When the tooth passes through the Hall-effect semiconductor sheet with current flowing in the camshaft position sensor, the magnetic field of the sensor deflects the electron flow direction in the Hall-effect semiconductor sheet to be perpendicular to the current direction, thereby forming a voltage signal in a short time. Inform the ECU: The first cylinder is just at the top dead center of the compression stroke at this time.

When the camshaft position sensor fails (such as unplugging the wiring harness plug of the camshaft position sensor), whether the diesel engine can be successfully started cannot be determined, and it should be considered according to the specific model. Even if the same electronic control system is used, some models can start, and some models cannot, which mainly depends on the control strategy of the system.

Differences between Crankshaft Position Sensor and Camshaft Position Sensor

The crankshaft position sensor is used to detect the engine speed, crankshaft position (rotation angle) signal and the top dead center signal of the first cylinder, and the compression stroke of each cylinder. It is the main signal to control the timing of fuel injection and ignition. As the airflow sensor, it is the main sensor in the centralized engine control system. In the computer-controlled electronic ignition system, the crank angle signal of the engine is used to calculate the specific ignition timing, and the rotational speed signal is used to calculate and read the basic ignition advance angle.

The camshaft position sensor is also known as the phase sensor and the synchronization signal sensor. Its function is to detect the angular position signal of the camshaft, and the ECU determines the top dead center position of the piston of a certain cylinder (such as cylinder 1), which is the important signal used to control the injection and ignition timing.

When the crankshaft rotates to a certain position (such as the top dead center of cylinder 1 or a certain angle before the top dead center), the camshaft position sensor inputs a position signal of the valve camshaft to the ECU, and judges that it starts to move upward at this time. Whether the piston running at the dead center is in the compression stroke or the exhaust stroke, the ECU can identify the compression top dead center of the 1-cylinder piston, so as to perform sequential fuel injection control, ignition control, and knock control. In addition, the camshaft position signal is used to identify the moment of the first ignition when the engine is started. Because the camshaft position sensor can identify which cylinder piston is about to reach the top dead center, it is also called the cylinder judgment sensor.

In a considerable number of vehicles, the crankshaft position sensor and the camshaft position sensor are made in one body, which are collectively referred to as the crankshaft/camshaft position sensor.

How to Detect a Camshaft Position Sensor?

The camshaft position sensor is also known as the engine speed or the crankshaft angle sensor. Its main function is to collect the sum of the angle of rotation of the crankshaft and the signal sent by the speed of the engine. The signal sent is input into the ECU, and this signal is used to determine when the engine ignites or injects fuel. This part mainly teaches you how to detect the camshaft sensor.

The detection of the camshaft position sensor is as follows:

1. When there is a problem with the camshaft position sensor, we can first check whether the resistance of the coil of the camshaft sensor is faulty. First, we need to disconnect the ignition switch, just unplug the touch sensor from the socket, and then use the resistance rating of the multimeter to check whether the resistance value of each port meets the standard value, if the detected resistance does not meet with the standard value, we need to replace a sensor assembly.

When the detection port is terminal NE-terminal G, the standard value in the cold state is 155-250, and the standard value in the hot state is 190-200; when the detection port is terminal G1-terminal G, the standard value in the cold state is 125-200, and the standard value in the hot state is 160-235; when the detection port is terminal G2-terminal G, the standard value in the cold state is 125-200, while the standard value in the hot state is 160-235. ;

2. When there is a problem with the camshaft position sensor, we can check the signal voltage of the camshaft sensor. First, we need to place the multimeter on the voltage position, and then put the multimeter on the No. 1 terminal of the sensor and on the No. 3 terminal. When the engine starts, the voltage value should be within the range of 0.2V- 1.2V; when the engine rotates rapidly, the voltage value should be within the range of 1.8V-2.5V;

3. When detecting the circuit of the synchronization signal of the camshaft sensor, first we need to disassemble the connector in the sensor, then switch the ignition switch to the “ON” state, and then start to check between the terminal A and the terminal C of the sensor. The normal voltage value should be 8V, but when the engine starts to rotate, we need to check the voltage between terminal B and terminal C of the sensor, and the voltage value should alternate between 5V and 0V.

What will happen if the camshaft sensor fails?

1. The camshaft position sensor is a positioning sensing device for cylinder identification. What effect does the camshaft sensor have on the car, which will cause the ignition to fail, making it difficult to start the engine, or the ECU cannot obtain the information fed back by the sensor, resulting in abnormal control of the engine’s intake and exhaust system and affecting its performance;

2. In addition, the damage to the camshaft sensor will also cause the crankshaft to reverse when the car is started, resulting in the problem of backfire of the intake manifold. Moreover, if the ECU cannot obtain information, there will be a problem of disordered fuel injection, which will lead to increased fuel consumption. The vehicle may also experience severe shaking, similar to the lack of cylinders in the vehicle;

3. Generally, when it is a bad camshaft position sensor, the engine fault light will be detected, so the fault indicator on the vehicle dashboard will light up, reminding the owner to check and maintain the vehicle in time;

4. When the device is in a normal state, the function of the camshaft sensor is to transmit it to the ECU electronic control unit according to the operation of the cylinder, so as to use the information to perform sequential fuel injection control, ignition timing control, and detonation control. In addition, the camshaft sensor can act as an emergency ignition in the event of a crankshaft sensor failure.

Conditions that can Cause a Camshaft Position Sensor to Fail

In the following part, we will discuss “what causes a camshaft position sensor to go bad“.

1. The camshaft position sensor element, circuit, or ECM is faulty;

2. Engine timing failure;

3. The variable timing adjustment part of the camshaft fails;

4. The target wheel of the camshaft position sensor is faulty or the gap is abnormal;

5. The crankshaft position sensor is faulty. The function of the camshaft position sensor is to collect the camshaft moving angle signal and input it to the electronic control unit in order to determine the ignition timing and fuel injection timing.

Fault Diagnosis and Removal of Camshaft Position Sensor

How to check if camshaft position sensor is bad? You can find an answer in the following part.

The car engine controlled by the electronic system is one of the products of high-tech progress. The electronic system can be used for different purposes through various types of sensors, actuators, or electronic control components so that the engine can be automatically controlled by the electronic system. The camshaft position sensor is one of these important electronic system control components. It is mainly used to check the starting and ending points of the piston inside the engine and accurately provide the electronic control system with a signal of the position of the piston. This signal will be used to determine when to ignite and the sequence of fuel injection. If the engine cannot receive an accurate signal, it will be difficult to start the engine, and it will be very weak when accelerating, the emission will exceed the standard or the speed will be unstable.

At this time we can boldly judge that there is a problem with the camshaft position sensor.

In order to confirm whether the camshaft sensor is faulty, we need to check it. Generally speaking, the manufacturers of camshaft sensors are different, and their production processes and quality are also uneven. At present, there are three main types of camshaft sensors on the market – Hall camshaft position sensor, photoelectric camshaft position sensor, and electromagnetic camshaft position sensor.

If the Hall camshaft position sensor is to be detected, it needs to be detected according to the principle of the Hall effect. When a current passes through the Hall element, if the direction of the current and the direction of the magnetic field of the Hall element are perpendicular to each other, a tiny voltage will be generated on both sides of them, which is called the Hall voltage by physicists. In order to determine whether the Hall sensor has sent a signal, it is only necessary to use the DC voltage to detect whether the average voltage of the Hall sensor is fixed. If you want to survey the photoelectric camshaft position sensor, you can disconnect the ignition switch, then use the sensor wire to connect to the plug, and then use a multimeter to connect to terminal 3, and then use a voltmeter to test. If not broken, the voltage should be above 4.5V, but if the voltage is 0, then the sensor is faulty.

Camshaft Position Sensor Replacement and Installation Process

In the following part, we will have a deep insight into “how to replace camshaft position sensor“.

1. Removal process of the camshaft position sensor

① It is recommended to disconnect the negative terminal of the battery when removing the sensor.

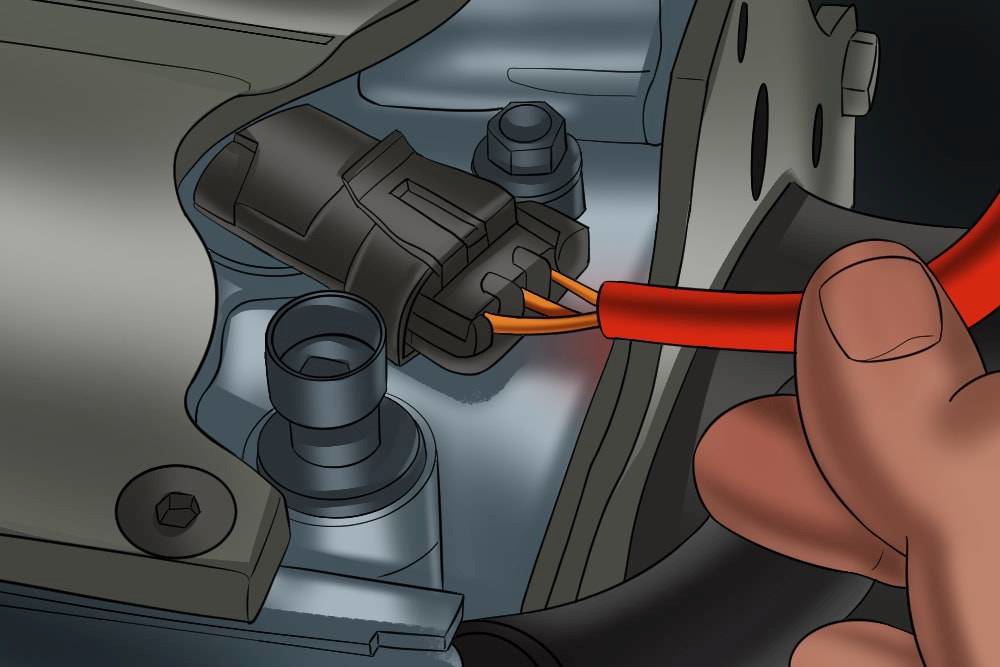

② Release the camshaft position sensor connector from the bracket and disconnect the connector.

③ Release the harness from the clip.

④ Remove the bolt and remove the sensor.

2. Installation process of the camshaft position sensor

① Clean the sensor and the joint surface.

② Fix the sensor, install the bolts and tighten to 10N·m.

③ Connect the camshaft position sensor connector and fix it on the bracket.

④ Connect the ground terminal of the battery.

For more informative blog posts visit our blog page: https://beingcounsellor.com/